A Complete Guide for Metal Casting

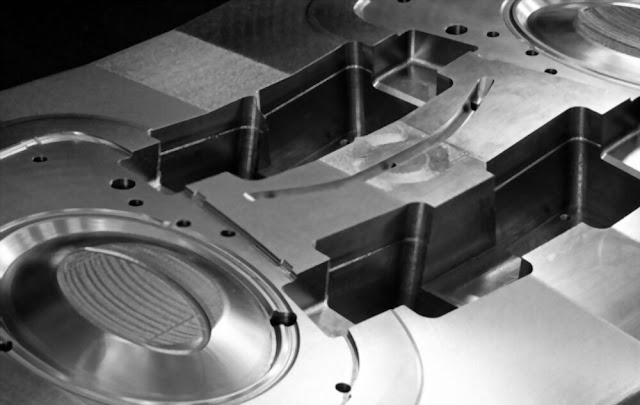

Every successful video production project depends on pre-production preparation. And one of the most important elements is casting. When the right talent is cast for the role, not only will the final image and project look better, but the shoot will also run more smoothly. Exactly the same; behind every successful solid metal object or any equipment, there is a casting process. Now, what is the metal casting process? Metal casting is a process of making objects by pouring hot melting metal into an empty shaped space. The metal then cools down and hardens into a form given to it by shaped mold. The casting process is cheaper than machining a part out of solid metal. There are different casting processes, like the sand casting process, gravity dies casting, pressure dies casting, lost-foam casting, plaster casting, and short run casting in Illinois . Have you ever been to a foundry? This is a place where metals get their shape. In simpler words, a foundry is a factory where ...